High quality

Comfortable

Certified

Promptness and reliable

Top Secret

At the beginning of the year a mole crept into our company and almost stole secrets from the development department. Fortunately, James was able to expose and apprehend the spy!

After processing the events, a film was produced - using the reconstructed information and footage from the surveillance cameras - that revealed the course of events and shows James chasing the mole across the company.

Enjoy watching the movie!

About ELKA

For over 45 years, barriers and gate opener systems have been the focus of our work. Our development department analyses constantly new market requirements and develop new products. In close cooperation with the quality management, the production department manufactures our first-class barriers and gate openers systems.

We stand for cohesion, we think long-term and we are proud of our team, particularly of some employees, who have been working for ELKA for over 20 years. Benefit from this experience and have a look behind the scenes. ELKA your reliable partner.

Reliable production in Germany

We attach great importance to the use of high-quality components and an optimal assembly process. All incoming goods are inspected in accordance with our technical specifications and checked very precisely using a 3D coordinate measuring machine. In a computer-controlled machining center, aluminum profiles are milled with millimeter precision.

This enables us to guarantee precisely fitting components and an optimal assembly process. Our modern production processes are regularly monitored and optimized and each product is subjected to a comprehensive final inspection and function test after assembly.

They only leave production if they have been successfully tested. This is how we meet our high quality standards.

In-house development

The development of our comprehensive product range takes place at the Tönning site from the first idea to production readiness. Customer requirements are taken into account as well as environmental or market requirements. First prototypes are created with the help of a 3D printer.

ELKA products stand for durability, high quality and easy operation. With the help of our 1,000 sqm test area, every product is extensively tested for quality, safety and reliability.

Fast order processing

Our standard product range is available at short notice, so that our customers can meet tight schedules without delay.

Benefit from our experience: Whether short-term offers, technical questions, individual customer orders or help with transport processing - we support you during the complete order processing.

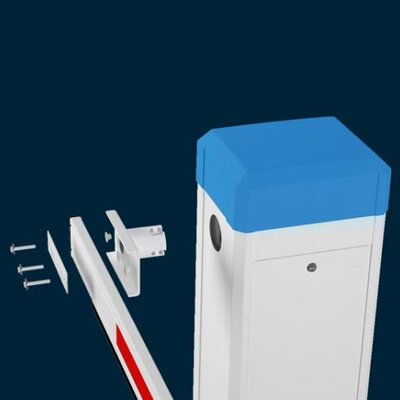

Easy installation and operation

ELKA products are pre-assembled in order to keep the installation effort on site as low as possible. The detailed installation instructions ensure that our partners can work optimally. If you have any questions, we will be glad to assist you by phone.

TIP: Our barrier systems can be conveniently programmed and operated via the "Easy Control" software or via the new ELKA ECON App.

It all started with a garage door opener

The history of ELKA began in 1979 in Kating, when the then 28-year-old Hans-Friedrich Eller founded a company to sell a garage door opener with toothed rack technology, which had previously been developed by his father.

Production started in the cellar of the parental home. By 1985, a nationwide network of resellers had been established, which carried out sales to end customers, assembly and service.

High up

In 1988 the cellar became too small for the 6 employees and ELKA moved into a 400 sqm hall of a former crab factory near the harbour in Tönning. An extension of the product range with slide gate openers, swing gate openers and barriers was well received by the customers. First international business relations with customers in Denmark and the Netherlands were concluded.

Until today

In March 1992 ELKA moved with 12 employees into the newly built 800 sqm company building in the Dithmarscher Street in Tönning. In the following years the company was expanded step by step.

Factory 1

Today, the company premises comprise a 5,000 sqm production and office building. 102 employees develop, produce and distribute ELKA products in more than 80 different countries worldwide.

Factory 2

All components, for which precise milling work is required, are manufactured in Factory 2. The work is done in a computer-controlled machining center. In the future, we will use the capacities gained to manufacture new products and to future-proof our range.